Your measurement sessions from process to Cloud

Data is the new oil and the linchpin of business strategies. Today, with digital transformation underway, traditional data acquisition systems are being merged with solutions based on new digital models of sharing. The combined use of acquisition, test and measurement instrumentation is proving to be a key lever for implementing an effective diagnostics, maintenance and testing strategy, as well as general process optimisation (reducing waste and non-conforming products, increasing efficiency and productivity, etc.).

There are situations in which a company's data collection systems can be used in a variety of ways. There are situations where Industry 4.0 is implemented without a real strategic vision and awareness of the importance of data and its integration. Distributed systems and disaggregated data cause information dispersion, errors and waste of time. Having aggregated and uniformly available data is a critical success factor.

For this reason, to be able to analyse and use information more effectively, it is necessary to integrate data optimally; particularly with the spread of new Cloud and Big Data management technologies. Integration solutions generally include some common elements, such as a network of data sources, a master server and clients accessing data through that server. A data integration solution is a must for the modern company, essential for improving decision-making processes and increasing the competitive edge.

DATA ACQUISITION

Data acquisition systems, often abbreviated to DAQ software or DAQ (Data Acquisition System), make it possible to monitor the process to be controlled, verify compliance with validation and production control procedures, improve customer service (certified products), support management systems (quality, energy, environment, safety).

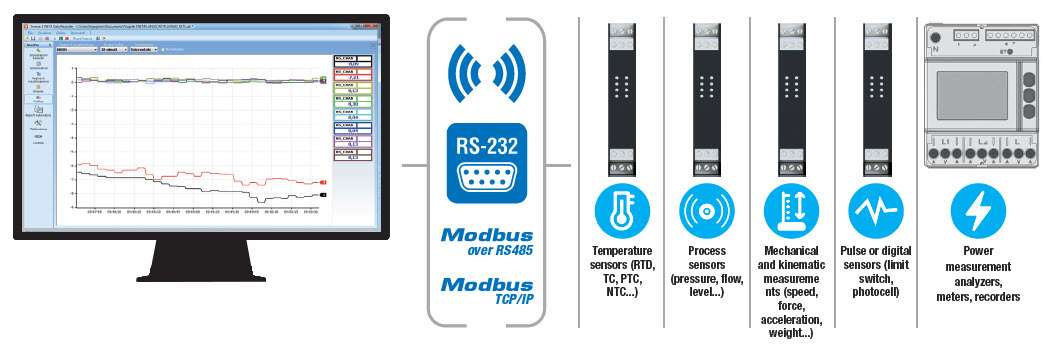

Data Recorder 2.0 is a SENECA software solution. A powerful, scalable and cost-effective Windows PC-based open recorder, ideal for professionals, maintenance workers, students, researchers, designers and departmental technical managers. The physical data acquisition is performed by SENECA Z-PC Series distributed I/O modules (with or without CPU), and in general by any standard Modbus RTU slave or Modbus TCP Server device thanks to the possibility of managing multiple serial or Ethernet connections simultaneously.

HIGHLIGHTS

- Use without specialist training

- Ease of configuration

- Schedule recordings

- Flexible, multi-format trend and historical data display

- Mathematical functions and equations of state

- Integrated alarm management functions, reports and mathematical calculations

- Data storage and export in a standard format

APPLICATIONS

- Testing, measurement and simulation sessions

- Testing benches

- Electronics labs

- Laboratories for teaching

- Test rooms

- Climatic chambers

- Engine rooms

- Industrial ovens

- Environmental measures

- Energy measures

- Plant inspections

DATA INTEGRATION

Integrating as much data as possible is essential for several reasons. To search for hidden patterns and relationships between different sources or manage data types, such as semi-structured or unstructured data, cannot be stored with traditional technologies. It is clear that, rather than the volume of data, the value that can be extracted comes from the correlation of a variety of data sources, types and formats. From this premise, it makes sense to talk about Data Integration as an essential prerequisite for developing advanced analyses from which new knowledge can be extracted.

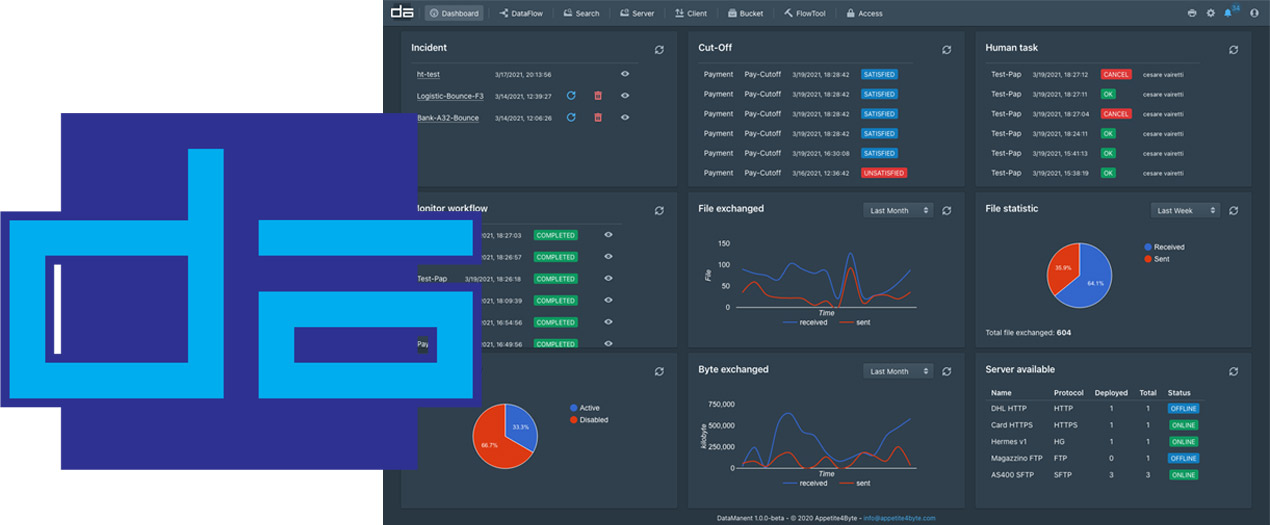

An example is Appetite4bite's DataManent cloud solution. A cloud-native Business Integrator Suite / MFT that transmits the data collected by the Data Recorder software onto the proprietary cloud platform making it securely available on workstations or mobile devices. A heterogeneous data integration, interchange, publication and governance system that offers modularity, reliability and maximum efficiency.

HIGHLIGHTS

- Quick implementation and customisation of the cloud system

- Support of the main communication protocols AS2, FTPs, HTTPS, SFTP, email, etc...

- Support for EDI, API, flat file, spreadsheet, JSON and XML formats

- Interface with intuitive and advanced dashboards

- Open access via API to locally captured and recorded data

- The any-to-any data transformation engine

BENEFITS OF THE INTEGRATED SOLUTION

- Real-time visualisation of all data acquisition sessions

- Monitoring and historicization of processes to be controlled

- Reduction of errors due to information dispersion

- Reduction of time to catalyse data from multiple sources

- Easy distribution and integration of data with ERP, CRM, SCM, SCADA, etc...

- Compliance verification with validation procedures

- Improved production control

- Better customer service (certified products)

- Improved efficiency (quality, energy, environment, safety)

Do you want to know more? Contact us

EN

EN