Remote control for wastewater treatment and rainwater lifting

A remote control system on a IIoT platform shelters the main Mercedes dealership in Rome from the floods of the Tiber. It is the one realized by Cogeco with SENECA (data acquisition and local control) and Rilheva (supervision and alarm management) technologies.

***

Mercedes-Benz Roma was born in May 2002 from the partnership between DaimlerChrysler Italia and the Nuova ABC Group. Today it employs about 585 people in the sales and service of the Mercedes-Benz and Smart brands. It is the largest commercial reality in the world for Mercedes-Benz Cars outside Germany and the first smart Center in the world for sales and service volumes.

As part of this project, the headquarters in Rome North of Via Salaria, one of the two main branches of Mercedes-Benz Rome, was built. This office has made use of Seneca and Rilheva remote control technologies, as well as Cogeco system integration, to manage the lifts and the purification plant at the service of its own plant.

Fig.1 Mercedes Benz headquarter in Roma (North)

System functionality

The one realized is a remote control system for wastewater purification and rainwater lifting. The hardware for data acquisition, control and local visualization is provided by Seneca. Supervision and IIoT platform are signed Rilheva. The fiber optic data communication network, FTTC, is provided by the client Autostar Immobiliare. The system has the purpose to report failures, the operating states of electromechanical equipment and measurements of analog signals related to operating levels and temperature. It also has the function of bidirectionality allowing the sending of commands from the system expires via web or mobile app to the plant for the start-up or shutdown of machinery.

Reports are made in 3 ways:

- Tramite local HMI device (display on control panel) which receives digital and analog 4-20 mA signals directly from control panels and level probes.

- Tramite Scada via web interface or mobile app, in this case, the RTU communication device sends and receives signals via bi-directional MQTT protocol over the data network

- Tramite email, where only alarm messages will be sent

Automatic operation logic has been implemented where when a temperature threshold taken from the blower room (50°C) is exceeded, the state of the machine is switched by acting on a relay in the blower panel. The power supply of the auxiliary circuit is then interrupted preventing the operation of the blowers until the temperature returns to a value of 45°.

Customer Benefits

The system realized allows the real-time control of the progress of the purification plant and of the lifting stations. This is a very important benefit because the entire structure serving the Mercedes branch in Via Salaria is located near the Tiber river. In case of heavy rainfall, the entire structure is at risk of flooding. The realized system allows to control the raising of rainwater in the lifting and in case of lack of automatic start of the lifting pumps is given the possibility to activate it remotely. It is also implemented the functionality of sending alarms to allow maintenance teams to intervene in case of machinery anomalies or in case of high level of one of the lifts.

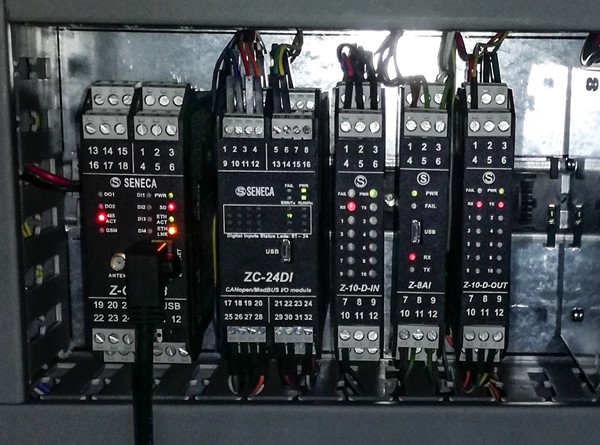

SENECA IIoT hardware

From the hardware point of view, the remote control system is based on Seneca hardware. In particular, the heart of the system is represented by Z-GPRS3, data logger unit with remote alarm, remote control and telemetry functions. Like the high smart SENECA dataloggers, Z-GPRS3 is a solution able to meet the growing needs of data collection, real-time analysis and integration with IT systems. Ё available with integrated UPS, integrated I/O channels, dedicated programming and visualization software, support for serial and Ethernet communication, GSM/GPRS modem and integration with Cloud solutions.

In the specific case the device is appreciated for the support of the MQTT protocol thanks to which the data communicated on Ethernet or Fieldbus, can be transmitted to the SCADA / Platform IIoT in a simple and secure way, thus analyzing in real-time the data coming from the plant. The hardware supply is completed by several analog and digital I/O modules (SENECA Z-PC Series) for data acquisition, a 7" touchscreen operator panel (SENECA VISUAL Series) and some temperature and level probes.

Fig.2 Detail of the automation panel with SENECA hardware

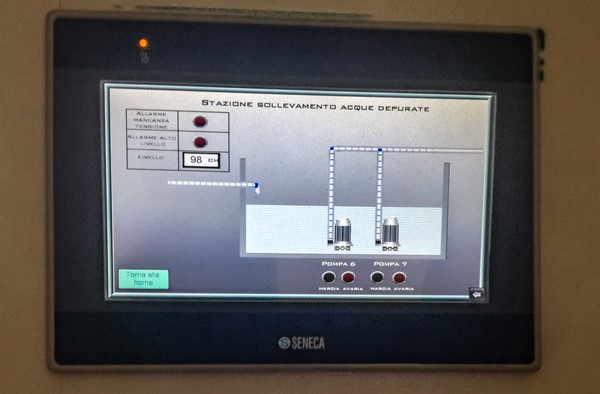

Local HMI

The local HMI consists of SENECA Visual4 (7" operator panel with LED-backlit display 800x480 resolution). The terminal allows to display system data, give commands, manage alarms and anomalies. You can access the application as "conductor" or "supervisor" to the panel, activating the commands that act on the electromechanical equipment.

When the system receives alarm messages these are shown in the bar at the bottom of the main video page. As long as the anomaly is active the error message will be scrolled through the bar, when the alarm ceases it will no longer be visible.

The lift control screen shows the operating status of the system with the indication of the LED alarms, the real-time indication of the level of the wastewater inside the tank and the indication of the level value in numerical format. The control page is completed by the pump control that can be activated by pressing the image of the corresponding pump. The trend page is also extremely useful and can be used to immediately display the 24h graph of analog signals, the level of rainwater, black water, purified water.

Fig.3 VISUAL4 lifting station control video page

Rilheva IIoT platform

Rilheva IIoT Platform, also available as iOS/Android app, is an innovative digital platform with which you can securely access remote devices with VPN technology and monitor processes with a Scada As A Service system. The modular design and simple setup make it easy to add or remove plant elements without downtime. Rilheva IIoT Platform allows you to design custom dashboards in minutes, define and historicize process KPIs, receive alarm notifications directly on the smartphone.

In the specific case, the signals coming from the SENECA RTU are sent to the URL https://portal.rilheva.com. From here you can log in once you have authenticated your user profile. The home page shows the status of the 2 systems, the virtual Test one (used for the operating status of the equipment in the dashboard) and the real one that shows the operating status of the equipment. The activation of the commands, typically the switching on and off of the machines or the restoration of the automatic operation of the same, is possible only to the users with the necessary permissions.

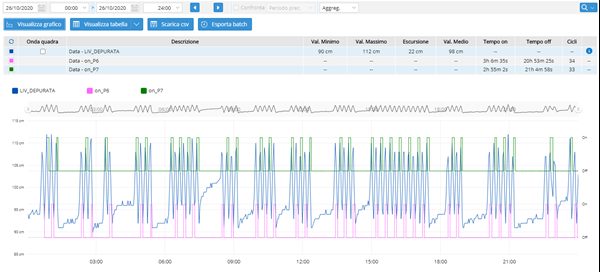

The platform also provides a "history & trend" section where you can view the graphs related to each signal (e.g. levels, hours and states, alarms) or the history of the readings. In terms of supervision Rilheva IIoT Platform allows an abbreviated graphic display of the plant, divided into different sections: sewage lifting, purified water, rainwater, equipment operating status (on, off, anomaly) purification plant with indication of the connection and with the graphical, numerical and colourimetric representation of the wastewater level. When they are active, the alarms, besides being visible in the start page and in the status tab, are sent by e-mail to the recipients in the address book. The message contains the name of the signal in alarm, the description of the type of alarm, the time and date when it occurred. There is also an alarm return email.

Fig.4 Page Trend platform Rilheva

EN

EN