LET'S technology for revival and lifting device management, remote control and SCADA integration

The SENECA remote control for the management of the peripherals for the relaunch and lifting of the water network has allowed a consortium in Vicenza to renew its technological systems deeply. A totally "Made in Italy" and tailor-made solution.

The manager of the Medio Chiampo water service has set himself several objectives to be achieved, such as equipping himself with innovative technologies to improve the service rendered to users, optimize work and interventions, and make plant operation and maintenance activities more economical and efficient. The Vicenza-based company has radically renewed its technological systems by choosing Seneca remote control to manage the relaunch and lifting peripherals as well as for integration with Movicon SCADA. A solution entirely "made in Italy" made to measure.

Medio Chiampo manages the integrated water cycle for the municipalities of Gambellara, Montebello and Zermeghedo in the province of Vicenza, for a served population of about 12,000 inhabitants. The company manages the sewerage and industrial wastewater treatment services through mixed-type plants and infrastructures. The potential of the treatment plant exceeds 400,000 inhabitants equivalent, compared to 20,000 inhabitants equivalent of the city line.

Fig.1 - Medium Chiampo wastewater treatment plant

A system that involves wells, pumps, and tanks

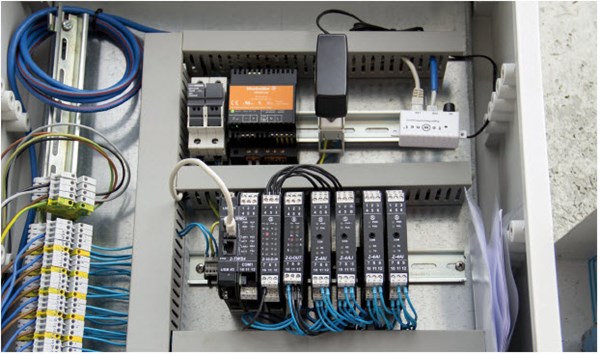

The implementation of the remote control system realized with Seneca technology involved wells, pumps and storage and relaunch tanks for the three water systems (Montebello, Zermeghedo, and Gambellara). In total, more than 300 points distributed over twelve peripherals are managed. The control is based on Seneca Z-TWS4-S multifunction web server unit, programmable with Straton platform. These units are networked ModBUS with analog I/O modules (Z-4AI) and digital ModBUS (ZC-16DI-8DO).

The automation logic carried out by the Z-TWS4-S controllers via Straton SoftPLC concerns the management of measurements and monitoring of the level thresholds of the storage tanks, the rotation of the relaunch and lifting pumps and local alarmism. Additional peripheral stations are managed by the Z-PASS2-S remote controller, an IEC 61131-3 logic unit with integrated Ethernet/3G+ router and VPN (Virtual Private Network) functionality. In addition to the standard automation functions, Z-PASS2-S allows you to carry out remote maintenance of your plant comfortably and safely using the public internet network. For this part of the system, future expansions are planned with the installation of additional peripherals based on the Z-PASS2-S remote controller.

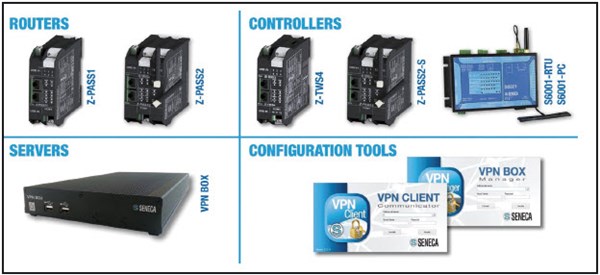

Fig.2 - SENECA LET'S VPN architecture components for remote control over LAN network

The entire geographical area of the aqueducts is covered by the remote network

From the point of view of communication, the remote control system has been designed to cover the entire geographical area of the aqueducts managed by Medio Chiampo; the different conformations of the land have been taken into account, with the aim of centralizing the numerous signals coming from all the plants in a single control center that coordinates the operators available for any interventions on site. Communication is developed partly via 3G+/GPRS network, and partly via UHF 869 MHz and NBMF 169.4 MHz radio (thanks to Seneca Z-AIR and RM169 radio modems) at free frequencies that do not require government licenses or authorizations for use.

As far as the supervision and management of maintenance are concerned, the HMI stations at the control center report the status of the alarm and display the situation of the controlled stations on special graphic pages. On a typical graphic page relating to a station, information on the status of the pumps, level, and flow measurements and the status of the electrical network are displayed. The SCADA application developed on the Movicon platform is designed to manage the availability of operators with an alarm notification system that depends on the area and time, with the consequent optimization of work shifts and maintenance costs. But in summary, what benefits can the customer enjoy? First of all, the standardization and centralization of communications, then the optimization of work shifts, the reduction of maintenance costs and the alarm notification system.

Fig.3 - Detail of Seneca peripheral panel

What is VPN technology and how it works?

VPN (Virtual Private Network) is a communication network that allows the transmission/reception between geographically distant devices (PC, CPU...) as if they were physically connected within the same private network but using public infrastructure. In the industrial field, it supports the connection of decentralized Ethernet subnets, containing automation and control equipment such as PLCs, inverters, HMIs, serial devices, sensors, actuators and so on. The OpenVPN protocol adopted by Seneca allows creating a private communication channel on an open communication infrastructure (internet, 3G+ telephony network). This solution guarantees compatibility with dynamic IP systems that are not particularly expensive in terms of SIM subscriptions, and a high level of protection thanks to the use of the OpenSSL encryption library and SSLv3/TLSv1 protocols. SENECA VPN remote control directly manages the devices through VPN tunnels and static IP 2G/3G+/4G. VPN technology is integrated both in the communication modules and in the VPN server connectivity module.

EN

EN