Why is it important to monitor power quality?

A Bloomberg New Energy Finance analysis last year found that photovoltaics and onshore wind are considered the most economical sources of electricity generation for at least two-thirds of the world's population. This is good news, and there is also good news in energy storage, where storage solutions are becoming even more technological and economically attractive.

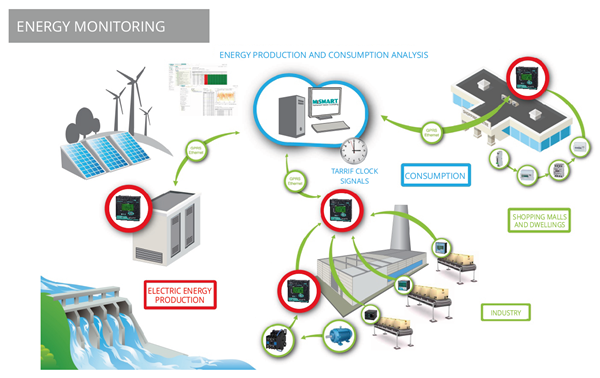

As there are more and more manufacturers of wind turbines and photovoltaic plants for energy production around the world, there is a growing need for continuous monitoring not only of the quality of the committed energy but also of the Point of Common Coupling (PCC): the point at which the local power system of the generating plant connects to the public utility's electrical system, such as the electricity revenue meter or the power plant designated to interrupt, separate or disconnect the connection between the generating plant and the utility's grid.

The electrical parameters of these plants fluctuate continuously and depend on many factors such as wind and sun. The installation of continuous, high-resolution recording and monitoring devices allows the utility, and/or operators of the given plant, to ensure compliance with grid requirements in terms of energy production, energy consumption, or both.

Energy quality monitoring has technical, economic, and legal implications; our experience shows that many energy quality events, while often within the range of tolerated events, can still be a source of problems for both energy producers and consumers.

The causes of these problems can be found in the following table.

The causes of these problems are manifold:

- VOLTAGE Amplitude deviation: caused by the variation of active and reactive power absorbed by the loads, by the action of transformers with a variable ratio under load, or by the connection of capacitive or inductive loads

- FREQUENCY deviation: caused by the presence of non-linear loads and transformers in saturation (the phenomenon of harmonics or voltage waves with a frequency equal to multiples of the fundamental frequency (50Hz for Italy)

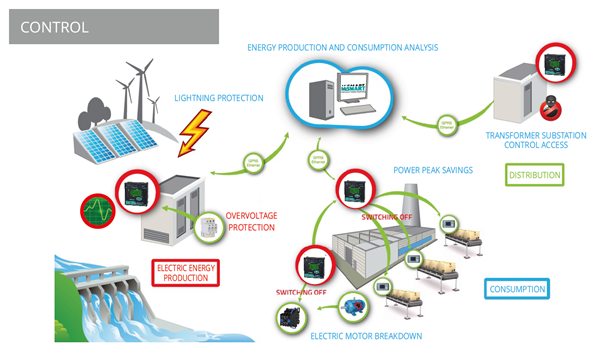

Insufficient energy quality is often the cause of many problems in industrial processes:

- DAMAGE to machinery (overheating of electric motors = reduced motor life)

- NON-CONFORMITY in production (machines do NOT work at design conditions)

- INTERRUPTION in the production (continuous intervention of the safety system - line disconnection)

- Increased energy costs (higher consumption and possible penalties applied by the grid operator)

The need is therefore to trace these events by means of a precise investigation of the quality of the power supply in order to have all the elements that will allow a more in-depth analysis to be made after the event.

The ideal solution for analyzing the above anomalies is the use of a class A Power Quality Analyzer (PQA) analyzer capable of continuously recording and storing all network parameters including waveforms, high accuracy, high definition, and a long period of data collection. This type of power quality analysis enables the investigation and presentation of all electrical parameters according to applicable industry standards. The PQA records all data to the highest levels of safety and reliability without the need for triggers or thresholds.

In the case of photovoltaic systems, for example, the PQA allows continuous measurements of power quality at the common coupling point to be analyzed in high definition. In many cases, the measurements detect anomalies that are mainly due to changes in transformer status with consequent voltage drops/changes. These voltage anomalies, while still within tolerance standards, can over time lead to serious problems in the system.

Using a class A PQA you can observe, analyze in detail these events and make choices to prevent future problems or service interruptions.

Do you want to know more? Contact us

DE

DE