El telecontrol "inteligente" de la red de alcantarillado.

Intelligent networks are increasingly spoken of as regards remote control, i.e. high technology integrated systems capable of rationalizing consumption and improving services. In the case of GISI spa, a company for the Integrated Management of the Oglio Water Service, this objective was achieved by entrusting Grundfos and Seneca with the implementation of remote control of the sewerage plants. The inter-municipal system currently treats wastewater from a population equivalent of about 70,000 equivalent inhabitants, with a territorial extension of about 242 km2 and a sewerage network of several tens of kilometers.

The communal areas served concern both the province of Mantua (municipalities of Sabbioneta, Viadana, Dosolo, Pomponesco) and Cremona (Casalmaggiore). On the other hand, the rising costs of goods such as electricity, labor or spare parts have made it necessary to change strategy in the management of networks of sewage treatment plants and sewer lifts. In essence, the same administrative criteria used for production plants, i.e. those aimed at minimizing costs and increasing performance, have become widespread in public utility networks.

Currently, information technology and the development of communications allow the use of efficient and fast remote sensing systems, able to ensure maximum functionality and reliability. At the same time, these technologies aim to minimize the consumption of energy resources and tend to reduce the exposure of staff to expensive, repetitive and dangerous operations. For example, automatic systems for collecting plant data and reporting faults and anomalies provide a prompt and appropriate response to emergency conditions, as well as preventing water loss and possible environmental and plant damage.

Waste-water treatment plants at Cogozzo di Viadana (13,000 population equivalent)

Waste-water treatment plants at Cogozzo di Viadana (13,000 population equivalent)

Rational control of installations

The use of automatic control systems and remote control becomes particularly interesting where the plant is distributed over the territory and consists of various sub-systems. This is precisely the case with the wastewater outflow and treatment system managed by the GISI. The sewerage network is made up of several lifting and purification plants located on the territory of the district and coordinated in their operation. It should also be noted that in the absence of remote control, the operation of the plants is linked exclusively to the physical presence of the staff and the related intervention times. The remote control system created by Grundfos and Seneca, therefore, assists a vast sewerage network, of which the waste capacities of each municipality must be measured. The system also collects data on the operation of individual plants. Thanks to these data it is possible to evaluate the correct sizing of the pumps and wells, as well as their operation. Among other things, the system makes it possible to identify faults and their extent in virtually real-time, and to intervene before they cause spillways, floods, and other problems.

In terms of automated management, the system makes it possible to optimize the network, calculating the flow rates and intervening on them to make the flow at the inlet of the purifiers as constant as possible. The remote control system is an effective support to the activities of maintenance and monitoring of the plants. Each station is controlled by a remote control panel. In each site, there are also ultrasonic sensors, pumping systems, processing units and dataloggers for the storage of measured data and a GSM / GPRS system for the transfer of data to the central computer and mobile phones available. Among the "intelligent" functions of the system, there is the continuous and bidirectional communication between the peripherals and the supervision center, and a series of totally automatic and preset functions: measurement totalization, data collection, pump operation turn-over. The system is also designed to allow the future integration of remote control on lifting stations under development.

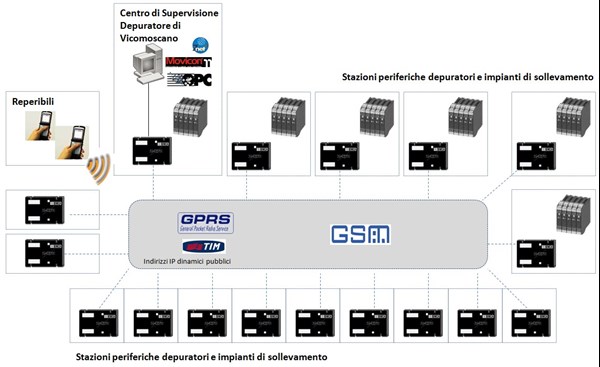

The architecture of the remote control system of the collection and purification plants of the municipalities of the Destra Oglio mantovana

The architecture of the remote control system of the collection and purification plants of the municipalities of the Destra Oglio mantovana

Remote control system summary

|

Controlled plant |

Inter-municipal collection and treatment network |

|

Equivalent inhabitants |

About 70.000 |

|

I/O (Managed Signals) |

More than 1.000 |

|

Purifiers |

5 |

|

Lifting stations |

12 (+10 in going) |

|

Hardware |

SENECA Z-PC system: Z-RTU remote control system and distributed ModBUS I/O modules |

|

Communication network |

GSM / GPRS |

|

Control logic |

Pumps rotation |

|

Supervision |

Movicon 11, OPC Server IO for communication via IP |

|

Supervision functions |

Datalogging, historical series analysis, alarm management, pump and system control from synoptic pages |

The remote control technology used

Z-PC series, SENECA's technology for data management and remote control, is based on open and internationally recognized standards. It includes devices and systems that support state-of-the-art communication protocols (PPP. FTP, HTTP, SMTP, TCP, Ethernet, OPC, IEC 870), at low cost and intending to ease of management. The Z-PC Series hardware, in both modular and integrated versions, is high performing. The master unit contains 4 integrated function modules (PLC, RTU, Web Server, Datalogger). The optoisolated, high-resolution I/O capable of powering the transducers is truly distributed and flexible. In particular, all GISI sewerage stations are controlled by Z-RTU, a device with 30 galvanically isolated signals with an integrated terminal block, 3 serial communication ports, and 1 Ethernet 10/100 Base T port. In the basic configuration, Z-RTU has 8 digital inputs (with internal or external power supply), 2 analog inputs (with selectable loop power supply), 4 digital outputs (SPDT relay), 1 analog output (voltage or current). This I/O density can be doubled (16 DI, 4AI, 8 DO, 2 AO) with an optional board and expanded with I/O modules distributed on bus and DIN rail Z-PC series. Z-RTU is equipped with an onboard industrial GSM/GPRS modem (or PSTN) to allow the remote management of alarms, diagnostics and data transmission on an event or on-call automatically on any standard communication network (PSTN, ISDN, GSM, ADSL, etc.). In a particularly small size (185 x 242 x 37 mm) and a sturdy aluminium case, Z-RTU offers excellent computing capacity (CPU μP RISC 32 bit - 20 MIPS) and memory (16 MB data flash, 8 MB RAM, 64 retentive variables via backup battery), the same as the modular version.

In terms of software, Seneca's programming strategy is based on the concepts of integration and openness in information processing. Configurations, programming, and remote control are developed based on IEC 61131 and offer maximum compatibility with any SCADA and Windows Runtime applications thanks to the OPC standard. Tunneling technologies for encapsulation and bidirectional data exchange over VPN (Virtual Private Network) are also supported. The configuration and engineering environment (Z-NET3) provides a suite of remote control functions (management of alarms, files, events via SMS, email, voice, etc.) and automation functions (pump rotation, hour counter, pulse totalizer, flow rate calculation, etc.) that are pre-filled and ready to use.

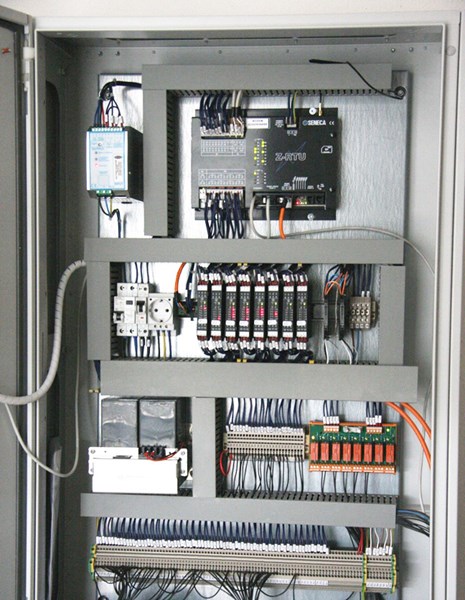

SENECA Z-RTU, apparato integrato di telecontrollo, cuore delle stazioni periferiche

SENECA Z-RTU, apparato integrato di telecontrollo, cuore delle stazioni periferiche

Peripheral stations

There are a total of 17 peripheral stations, including 12 lifts and 5 purification plants. The lifts are assisted by the automated management of 31 relaunch pumps with powers ranging from 2 to 18.5 kW. The purification network includes 4 main activated sludge plants. The purification cycle includes mechanical operations (lifting and grilling), primary treatments (desanding, de-oiling, primary settling), biochemical processes (denitrification, oxidation, nitrification) and final treatments (sedimentation, filtration, UV disinfection, thickening, anaerobic digestion, mechanical dewatering). The peripheral stations, monitored from the headquarters of Vicomoscano di Casalmaggiore through GPRS network, include over 1,000 I/O signals. The heart of the peripheral stations is represented by the Z-RTU remote control device that acquires up to 16 digital inputs and up to 8 analog channels, including measurements from magnetic level probes.

Each remote device controls 4 digital outputs: 1 for enabling electromechanical control (which therefore excludes the logic implemented onboard), and 3 for pump control. The basic configuration of the 18 peripheral stations (hardware and data) is carried out by means of Z-NET configuration software in compliance with IEC 61131 standard. The pump ignition control is implemented for all systems, based on a level acquired by the ultrasonic level gauge. The PLC logic that manages the rotation of the pumps continuously controls the running time of the pumps. When the starting threshold is reached (compared with the level detected by the meter), the algorithm selects the ignition of the available pump that has the shortest total operating time. Similarly, when a shutdown threshold is reached (compared with the level detected by the meter), the pump that has the longest total operating time is switched off. The number of pumps controlled in each station varies from 2 to 5. The hourly totalisation is progressive, but daily the totalisation of the daily data is historicized. All the events coming from the switching of the input signals (alarms and system states) and output signals are archived. The data stored in the log files also include the trends of the level and flow measurements. It is important to note that the pump rotation routine is a ready-to-use service that requires no additional programming. It is also an extremely flexible function. It allows you to automatically manage up to 8 pumps and to choose between 3 different control modes (based on alternation, time or operating priority). The event trigger can be selected on measurement threshold, time or digital contact.

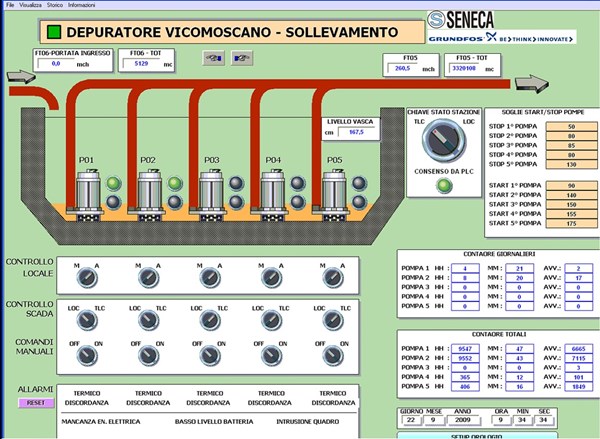

Detail of the control panel at the Vicomoscano di Casalmaggiore purification plant (40,000 population equivalent)

Detail of the control panel at the Vicomoscano di Casalmaggiore purification plant (40,000 population equivalent)

The communication network

The primary communication network of the remote control system is based on GPRS (General Packet Radio Service) mobile telephony technology. The stations are always connected in bidirectional mode. When they connect to the GPRS network, they communicate to a specific server the IP address that the service provider has assigned them. The transmission of the operating states is carried out by means of OPC technology (OLE for Process Control). In particular, the OPC SERVER IO software, developed by Seneca, acquires the dynamic, public IP address stored on the server.

At that point, the control center starts to communicate bi-directionally with the remote station. The systemic control of GPRS communication is fundamental. The remote control is designed to monitor the quality of the signal and perform an automatic error detection procedure. In the sites of the purifiers, there are UHF wireless subnets based on Z-LINK, Seneca LPD (low power device) radio equipment operating at 434 / 869 MHz. These devices remotely control the operating states of the pumps, retransmitting the data near the control panels, safely and reliably, and wirelessly, up to a few hundred meters.

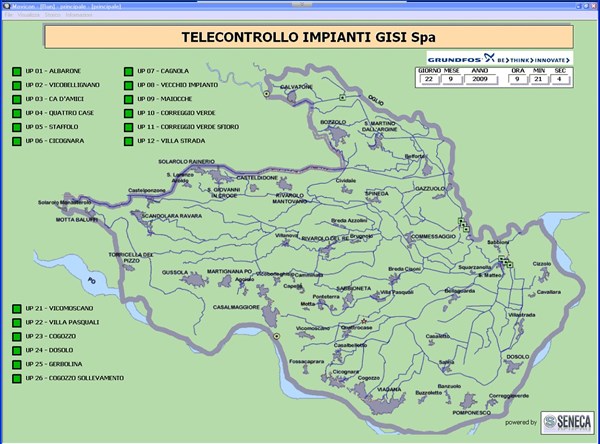

Supervision

At the station of the purifier of Vicomoscano, there is the control center. From this, through the Movicon 11 supervisor, the plant parameters of all the stations are monitored. The new version of the Scada Movicon installed allows the management of variables and data for thousands of I/O bytes, as well as the possibility to develop and control an unlimited number of synoptic pages.

Particularly interesting is the "Alarm Dispatcher" package, the Movicon component for event notification, which allows alarms to be sent to staff via voice synthesis, SMS, E-Mail, Fax, and real-time messaging services. All this with a high level of customization (user group, sending according to timetables, calendars, shifts and staff available in rotation). For each station there is a mask that allows you to enable or disable the sending of SMS to the available, depending on the alarm or the corresponding status.

The recording and management of process data in a simple and fast way are done through Ftp Server technology and Seneca software tools such as Z-NET RTU and OPC Server IO. Z-NET RTU is a remote control service for the hourly, daily and weekly scheduling of the download of historical data on one or more parallel connection rings. Z-NET RTU manages the connections with the remote stations (even in the event of an alarm) and the creation of the database in the central unit from which the display pages of the alarms and trends of the acquired quantities are then processed using OCX technologies. Finally, data management uses a Seneca tool called OPC Server IO. It is an OPC server software able to interface with any instrumentation that supports the ModBUS slave RTU or ModBUS TCP protocol and in particular with the Z-RTU remote control units. OPC Server IO, therefore, offers a single integrated environment for data exchange between the remote stations and the Scada. In addition, relying on a public FTP server (on the Internet), OPC Server IO is able to make a direct connection via the Internet via GPRS network (TIM) to the Seneca instrumentation located in the field. In practice, this type of OPC Server allows the supervision PC to function as a Modbus Master node.

Synoptic page with general map of implants

Lift station control synoptic page

Trend of level and flow measurements

ES

ES